end wall flashing detail

The advice given in this manual is consistent with the requirements. The lower edge of the flashing should extend about 12 beyond the face of the brick and have a downward bend to provide a drip.

CLICK TO ENLARGE Seal around windows carefully paying special attention to the head flashing and sill pan.

. Request DWG File for PG-LS-WALL-01-3D. Outside Corner Flashing Detail Typical - PG-LS-WALL-03-2D. The coping flashing locks into this strip then runs over the old wall.

330 769-3546 Toll Free. On center and a minimum of 10 ft. FLASHING GUIDE 3 Correct detailing of LYSAGHT roof and wall flashing has more than cosmetic importance - it is essential in ensuring the wet weather performance of the cladding.

10 Linear Feet Of Outside Foam Closures. The key to success with any flashing detail is to follow the shingle. The first detail shows the typical method of flashing a brick wythe.

The cap flashing is set in the mortar joint. End-wall flashing is applied where the upward slope of a roof meets a wall. Through wall flashing at the base of the walls should be located 2 or 3 50 or 75 mm above finished grade.

Specify which trim piece is needed and the roof pitch when ordering. Pole BarnPost Frame Building Trims. Hyload Headquarters 5020 Enterprise Parkway Seville Ohio 44273 Email.

The lower face of the Through the Wall Z Bar Flashing is extended past the end of the Vertical BlockingBacking Material an inch or two to cover the intersection of the Exterior Wall Covering and the end of the Vertical BlockingBacking Material. For chimneys specifically base flashing is the first of two types of flashing applied and sits below the second type of. As a result parapet walls can crack heave or bow.

In all cases make sure to detail the flashing membrane so that it sheds water. Step 1 Flashing 1 is a typical apron roof flashing. Now that youve prepped the Z-trim tops with tape sealant and folded the flashing ends down to overhang the gables you can proceed to fastening the flashing.

10 Steel Endwall Flashing at Menards. The wall side of the flashing can be covered with siding or counter-flashing and outside closures are necessary to seal between the flashing and the panel. The eave trim is located at the end of the roof panel near the top of the wall panel creating a beautiful.

The wallplate is then used to secure the rafter to. Joints are soldered or sealed see. Through-wall flashing is used in many areas of the country as shown in Figure 9.

The maximum parapet wall height is not to exceed the width of a 10-ft. Correct flashing and detailing will improve the overall appearance of the finished job. Plates and fasteners get installed at the seamvertically up the wall at 12 in.

Flashing detail for exterior insulated gable wall and roof. 10 White Endwall Flashing. Request DWG File for PG-LS-WALL-04-2D.

The ensures that theres a watertight barrier between the end wall flashing and the top of the Z. For front end-walls where roofing shingles meet siding the metal flashing strip should be bent using a metal brake to extend at least 2 inches up the vertical wall and at least 3 inches onto the last shingle course. Duro-Guard Fan Fold Fastening.

Ca reful design of flashing details to suit the application can help to. The flashing must extend up at least 8 weeps spaced a maximum of 24 OC and pea gravel are rec-ommended. To allow movement due to thermal expansion at one end of every.

Laps are heat-welded and the process continues until the wall flashing is complete. Moldable flashing tape is easy to form into an effective sill pan. 07 65 00 - Flexible Flashing.

This is particularly so for details such as door and window corners and for flashing that has exposed fastenings. For best protection add a metal drip cap at the top of the window caulked directly to sheathing. Ad Grace Flashing Seals Around Windows Doors Corners Areas That Can Allow Water To Enter.

The top edge of the base flashing is cleated to the new wall. High Wall Flashing Detail wih Intermittent Fastening. A common lock seam joins it to the base flashing which runs up the face of the new wall at least 9.

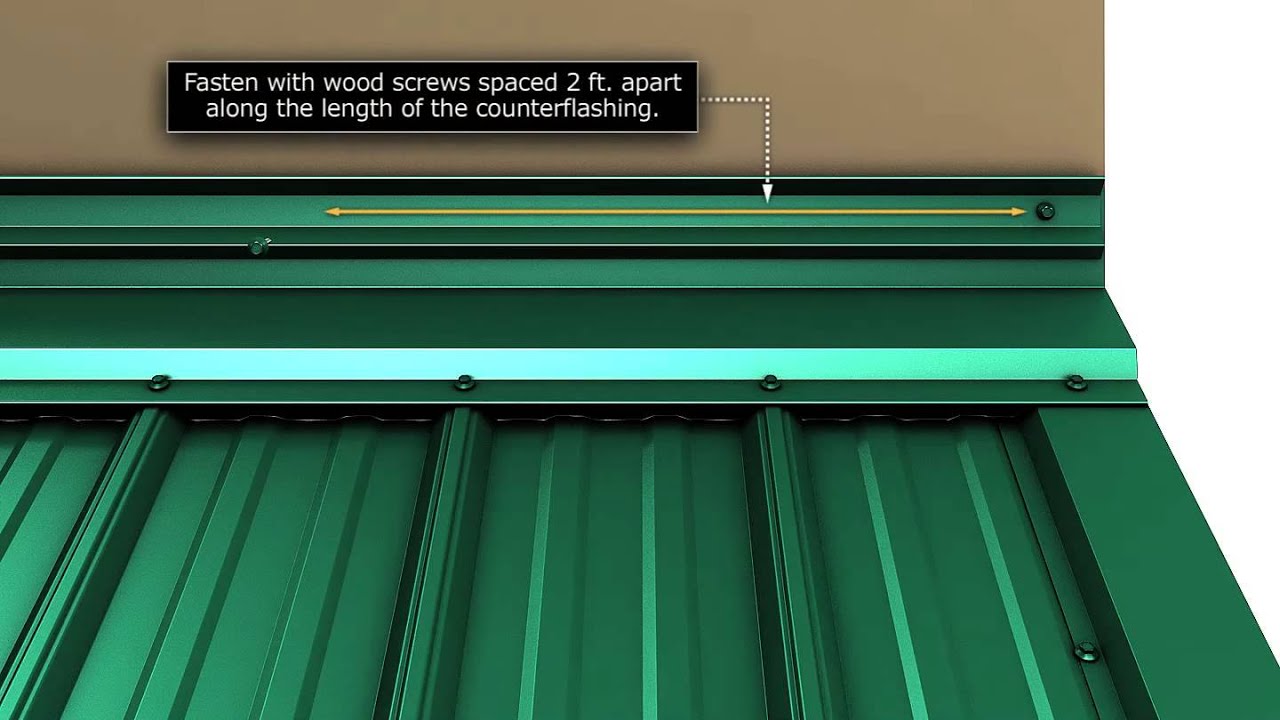

From any corner or end of wall. Prefabricated flashing end dam carry flashing ½ min. Endwall Flashing Installation.

The end wall flashing provides protection where a roof intersects with a vertical wall. End dams are constructed by cutting and folding the flashing material. Wall To Roof Flashing For Non-Wall Supported Deck Typical - PG-LS-WALL-01-3D.

Through-wall flashing is installed in the new wall then bent down to lap the base flashing and cleats. End dams should be constructed wherever flashings terminate within a wall to prevent water from simply flowing off the side of the flashing within the masonry wall rather than being directed to weeps where it can flow out of the wall. Inside Corner Flashing Detail Typical - PG-LS-WALL-04-2D.

End wall flashing detail Tuesday March 8 2022 Edit. Flashing must be installed by a skilled tradesperson if quality results are to be achieved. The final step in endwall trim installation is.

White_1567209-01 Menards SKU. Grace Vycor Plus Self-Adhered Window and Door Flashing 6in 9in 12in.

Pin By Silin He On Detail Expansion Joint Masonry The Expanse